Back

Compact cutting lines MLC

Cutting and slitting line with straightening unit, 1.25 x 1mm, 3 sets of blades, CNC

Ref. MLC1250-BD

Price and lead time: please contact us

Compact cutting line, reference MLC1250-BD, 1,25m useful working width, 1.2mm steel shearing capacity, 1,0mm steel slitting capacity, equipped with a numerical control, for feeding, slitting and length cut. It owns the same equipment than the model MLC1250 along with a straightening station

More info Optional complementary equipmentCutting and slitting line with straightening unit, 1.25 x 1mm, 3 sets of blades, CNC

> Product plus:

- Numerical control as standard allowing a complete management of uncoiling and slitting

- Length cut by guillotine shears providing power and rapidity

- Manual blades adjustment with wheel and counter allowing precision and quality of cut according to the thickness of the material

- Excellent accuracy of length cut +/-1mm

- Straightening station

NB: The cutting lines MLC are also available upon request wihtout slitting station.

Feeding selector: please contact us

> Standard equipment:

- Entry table with rollers including adjustable guides by lever with counter, 1,25m maximum width

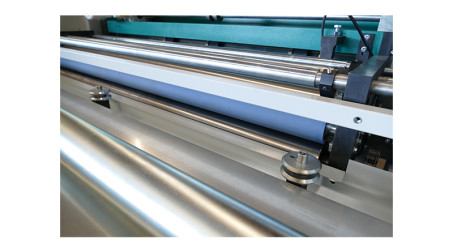

- Motorized feeding station (1 steel roller + 1 rubber-coated roller Ø 80mm)

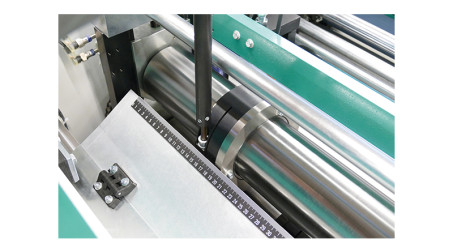

- Slitting station with ground shafts Ø 100mm, equipped with 3 sets of adjustable cutter blades Ø 154mm with reading on tool - Manual shaft adjustment by wheel and counter

- Minimum cutting width: 80mm between cutter blades 10mm at edge

- Set of reversing cutter blades mounted on one-piece blade-carrying blocks

- Maximum uncoiling speed: 20 m/mn

- Straightening station (3 steel rollers Ø 80mm - position reading on graduated screen)

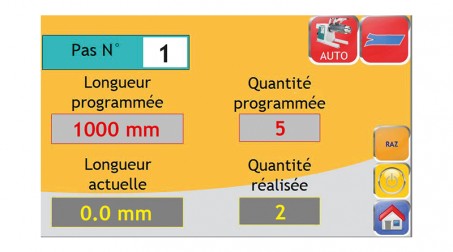

> Control console with:

- Color touch screen 7’’

- Lengths and quantities programs

- Naming and saving of programs

- Indication of raising or lowering of the upper shaft automatically given to the operator by the CNC

- Possible use of manual mode

- Daily counter and cutting accumulator

- Preventive maintenance menu

- Remote maintenance and updates via Ethernet connection (RJ45)

Product features

|

Weight (kg) |

1 200 |

|

Dimensions (mm) |

1 450 x 1 600 x 1 900 |

|

Power of motors Feeding / Straightening (kW) |

1,5 |

|

Power shearing unit (kW) |

1,1 |

|

Power rise of cutter blades (kW) |

0,18 |

| Power supply* (V) |

400V (three-ph + neutral + ground) |

|

Capacity Steel shearing S235JR (mm) |

1,2 |

|

Capacity Steel slitting S235JR with 3 cutter blades** (mm) |

1 |

| * Voltage choice to signal at the order | |

|

** Caution, the addition of extra set of cutter blades reduces the cutting capacity when slitting |

|

Optional complementary equipment

Shipping methods Shipping method

Delivery conditions Delivery conditions

Warranty Gaantie

Machines certified

French Origin Guaranteed

Machines certified

French Origin Guaranteed