Back

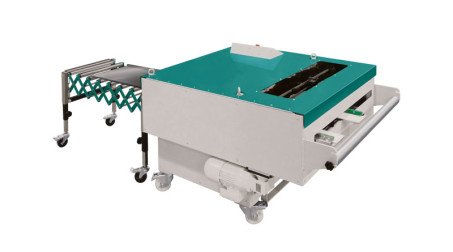

Workshop standing seam roll-forming machines PROBAC

Variable speed motor electric roll former for Standing Seam 220 V Electric Transversal Cutting and Slitting Integrated

Ref. PROBAC-HT-CE

Price and lead time: please contact us

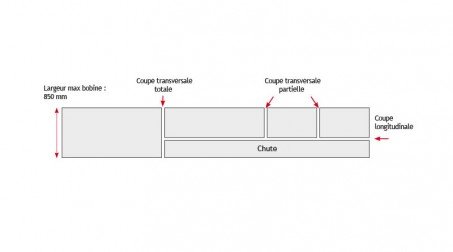

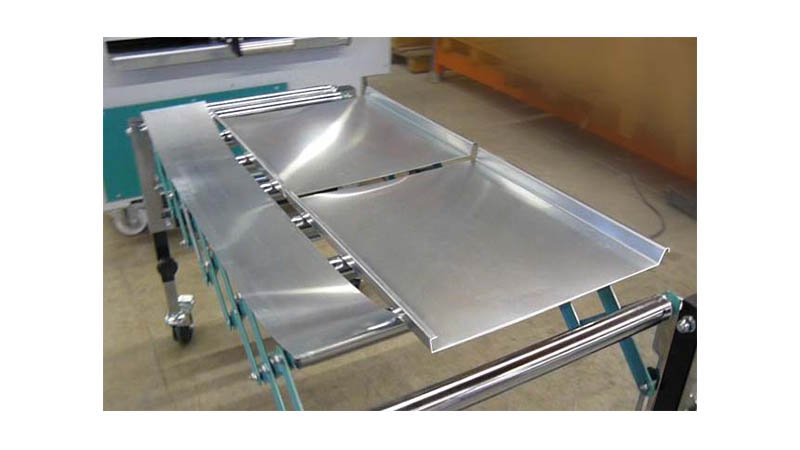

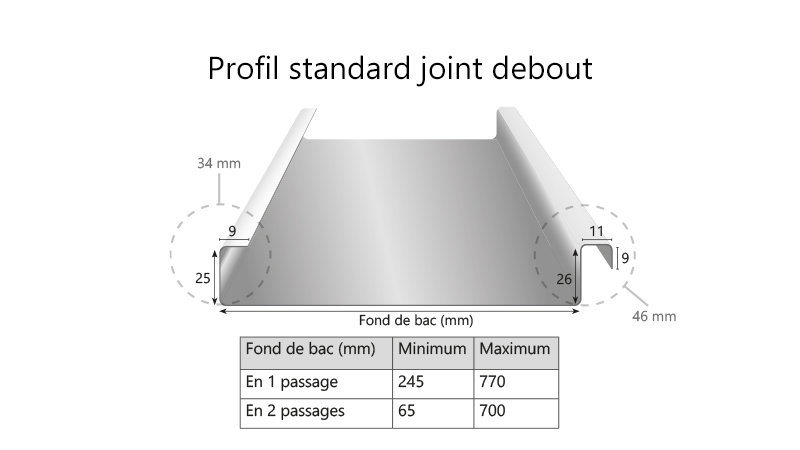

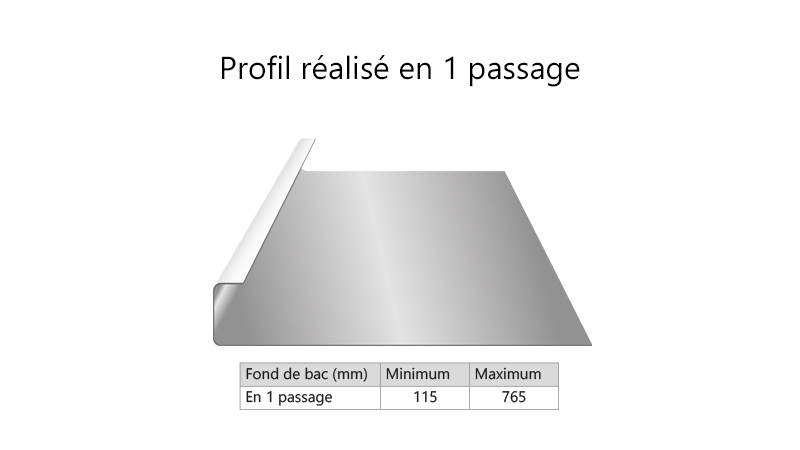

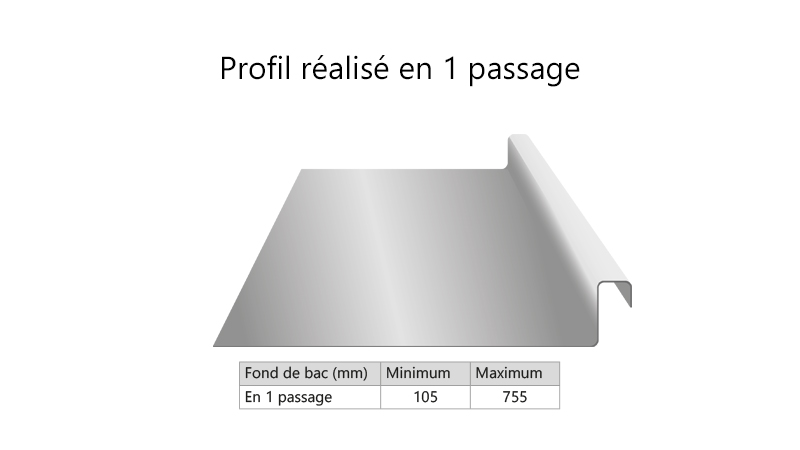

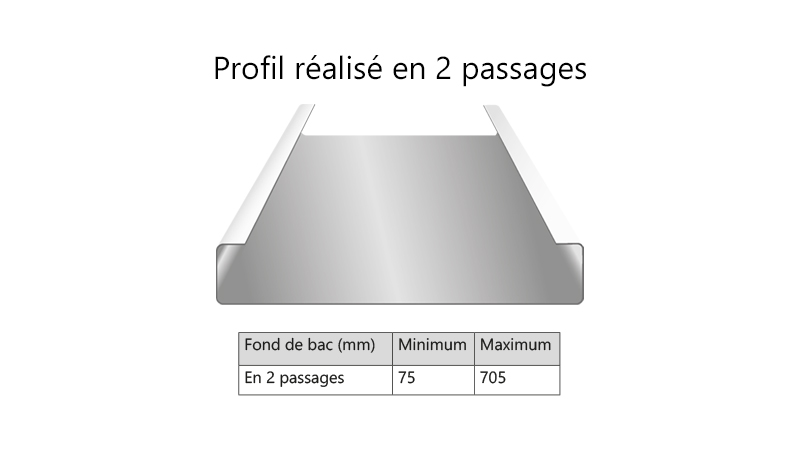

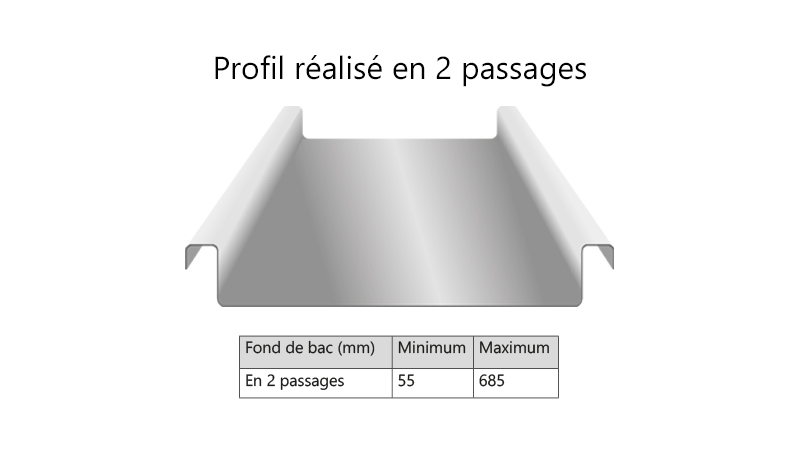

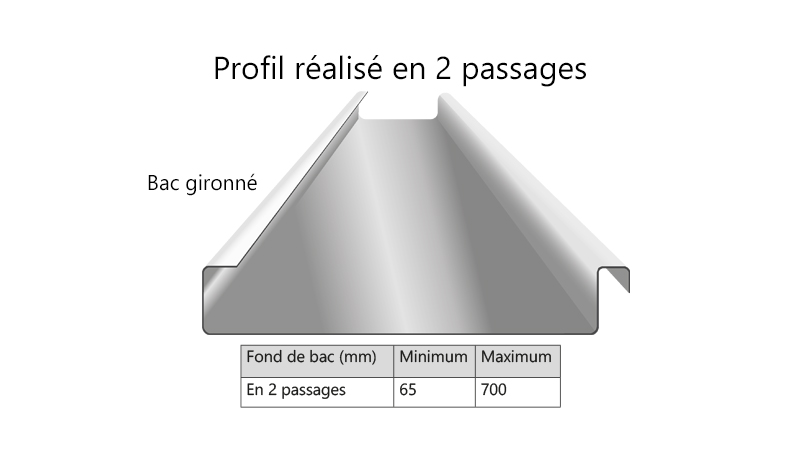

Electric roll-forming machine for building site or workshop, reference PROBAC-HT-CE for the production of standing seam profiles in parallel or concical trays. Check of the machine by numerical control with touch screen. Full or partial electric transversal cut and automatic cycle to produce several trays without intervention, longitudinal cut with or without roll-forming

More info Optional complementary equipmentVariable speed motor electric roll former for Standing Seam 220 V Electric Transversal Cutting and Slitting Integrated

> Product plus:

- Intuitive check of the machine

- Roll-forming rapidity 15m/mn

- Accuracy + / - 1mm in repetition over 4m

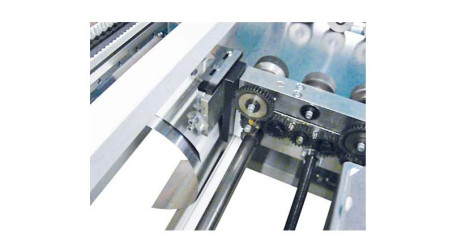

- Electric transversal cut

- Automatic cycles to produce several trays without the operator's intervention

- Fine adjustments by wheels

> Numerical control

- Speed + 50 %

- Console with color touch screen 7"

- 4 roll-forming menus at the operator's choice: manual mode, quick programming, memorized programs, specific programs for conical trays and first trays

- Dailay counter and accumulator of roll-formed lengths

- Preventive maintenance menu

- Remote assistance

> Standard equipment:

- Numerical control on color touch screen

- Roll-forming speed variator

- Integrated feeding

- Adjustment of entry guide of coil

- Adjustment of infeed width and tray width

- Entry guide on anti-marking roll slide

- Full or partial, electric transversal cut

- Automatic roll-forming cycles

- Longitudinal cut with or without roll-forming

- Tray length programming

- 7 sets of rollers

Product features

| Net weight (kg) |

526 |

| Dimensions (mm) |

1 600 x 1380 x 1 000 |

|

Capacity Zinc / Copper / 1050-H44 Aluminum (mm) |

0,8 |

| Power supply (V)* | 220V - single 20 A |

| Power (kW) | 1,5 |

|

Roll-forming speed (m/min) |

5 - 15 |

|

Length accuracy (repetitively) (mm) |

± 1 |

|

Minimum length of trays (mm) |

400 |

| Minimum width of slitting (mm) | 50 |

|

Slinging rings |

4 |

| * Voltage choice to signal at the order |

Optional complementary equipment

Shipping methods Shipping method

Delivery conditions Delivery conditions

Warranty Gaantie

Machines certified

French Origin Guaranteed

Machines certified

French Origin Guaranteed