Back

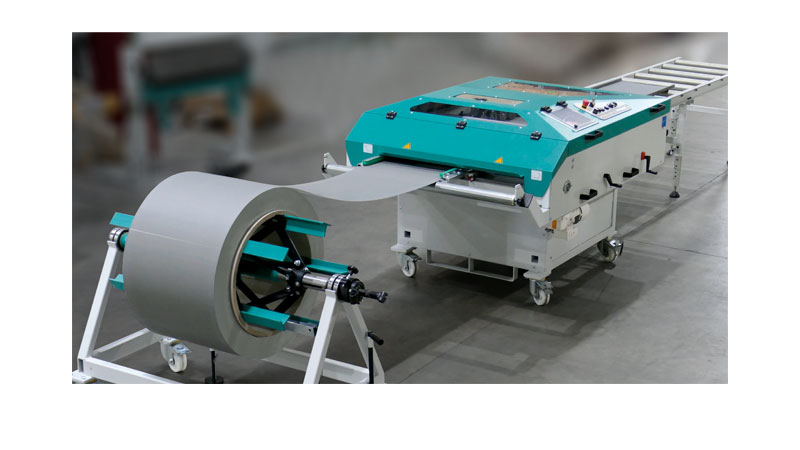

Workshop standing seam roll-forming machine PROBAC-HTEC

Electric roll forming machine for standing seam with CNC, Slitting and electric transversal cutting

Ref. PROBAC-HTEC

Price and lead time: please contact us

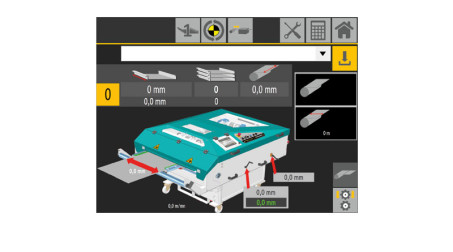

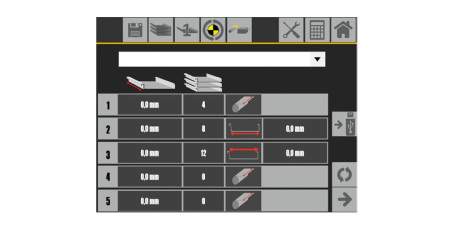

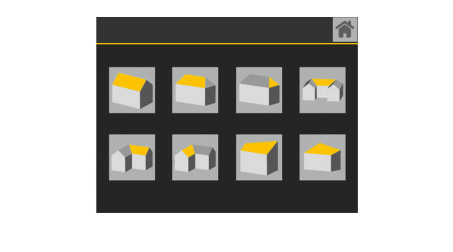

Electric roll-forming machine for workshop, reference PROBAC-HTEC for the production of standing seam profiles in parallel or conical trays. Check of the machine by latest evolution of digital control with 10'' touch screen. Full or partial electric transversal cut and automatic cycle to produce several trays without intervention, longitudinal cut with or without roll-forming, tool-free, quick-adjusting entry guide system. Automatic calculation of the number and trays dimension according to roof layout.

More info Optional complementary equipmentElectric roll forming machine for standing seam with CNC, Slitting and electric transversal cutting

> Product plus:

- Profiling rolls adapted for all materials,

no adjustments required when coil changing - 8 sets of rolls spread over a long length for a progressive profiling, reducing the « tulip » effect at the beginning and end of the tray

- Excellent regularity of profiling for every materials used

(natural zinc, quartz, pre-weathered, aluminium, copper galvanised and painted steel...) - Tool-free, quick-adjusting entry guide system for profiling different types of trays: single-sided, double-sided, conical and slitting operation

- Intuitive check of the machine

- Roll-forming rapidity, up to 20m/mn

- Accuracy + / - 1mm in repetition over 4m

- Electric transversal cut

- Automatic cycles to produce several trays without the operator's intervention

> Numerical control

- Latest numerical control with large 10’’ colour touch screen

and liftable protective cover - Step-by-step CN support for the operator in all profiling steps

to make the machine more user-friendly - Automatic calculation of the number and trays dimension

according to your roof layout - Speed + 50 %

- Console with color touch screen 7"

- Automatic calculation of material requirements

(material management for up to 10 coils) - Total and daily counter with profile length reset

- Maintenance menu informing the operator of the preventive maintenance actions to be carried out according to the accumulated profile lengths

- Remote factory maintenance via wifi or wired internet connection

- USB port for importing programs in Excel and exporting

> Standard equipment:

- Numerical control on 10’’ colour touch screen with protective cover

- Integrated in-feeding process

- Entry guide on « roller slide » to avoid marking the sheets

- Longitudinal cut with or without roll forming

- Full or partial transversal electric cutting

- Variable speed drive

- Tool-free quick adjustment of the entry guide and the slitting knife

- Adjustment of the strip and covering width

- Position adjustments of the left and right profiling roll sets by handwheel

- 8 larger set rolls diameters

- Braked wheels and handles for moving the machine

- Handling space for forks

- 4 roll-forming menus at the operator's choice: manual mode, quick programming, memorized programs, specific programs for conical trays and first trays, specific mode for «side by side» profiling for starters and conical trays, allowing easy adjustment of the profiling speed to ensure good tray support

Product features

|

Capacities Zinc / Copper / Aluminium 1050-H44 / Steel (mini/maxi) (mm) |

0.6 / 0.8 |

| Power supply (V)* 30mA differential circuit breaker protection |

230 V Single-phase |

| * Choice of voltage to be indicated when ordering | |

| Active power supply (kVA) | 4 |

| Dimensions (LxWxH) (mm) | 2055x1370x1180 |

| Net weight (kg) | 640 |

| CE conformity | Yes |

|

Variable profiling speed (min./max.) (m/min) |

5 to 20 |

|

Length accuracy (repetitively over 4 meters) (mm) |

± 1 |

| Maximum width of entry guides | 850 |

|

Minimum length of trays (mm) |

650 |

| Minimum slitting width (mm) | 50 |

|

Dimensions covering width |

|

| Standard standing seam profile, in 1 stage (min./max.) (mm) | 180 / 775 |

| Standard standing seam profile, in 2 stages (min./max.) (mm) | 75 / 775 |

| Male-male profile, in 2 stages (min./max.) (mm) | 85 / 785 |

| Covering width male profile only, 1-sided (mm) | 40 |

| Profile female-female, in 2 stages (min./max.) (mm) | 75 / 760 |

| Covering female profile only, 1-sided (mm) | 45 |

| Standard standing seam profile conical, in 2 stages (min./max.) (mm) | 75 / 760 |

Optional complementary equipment

Shipping methods Shipping method

Delivery conditions Delivery conditions

Warranty Gaantie

Machines certified

French Origin Guaranteed

Machines certified

French Origin Guaranteed